matgriff

-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

PW Shop

Posts posted by matgriff

-

-

20 hours ago, wyn said:

A D3 has 16 ECU's they all need reading and faults clearing with something like a GAP IID.

+1 on the above, if you own a D3 a GAP IID tool is worth its weight in gold, its an expensive outlay initially at around £350 for the blue tooth version, but it will save you hundreds in the long term, and they sell for not much less 2nd hand, so you can always recoup your outlay. Each tool is coded to a particular VIN number, which restricts it's use on other vehicles to basic diagnostics and resets etc, so you can use your tool to read the codes on other D3's but you can't perform some of the advanced diagnostic & calibration features such as coding new keys and calibrating the air suspension etc. The pro version of the tool as used by garages etc can work on any D3, but this costs considerably more.

-

On 04/01/2021 at 13:12, Centrepin said:

I agree its an easy job and to reset the brain instead of a thingy me bob you can static steer side to side full lock to full lock several times. For some unknown reason this clears most fault codes and does a reset

Not meaning to cause any offense here, but this is not correct information for a Discovery 3

-

16 hours ago, Daz1986 said:

So today fault codes where done!! Nothing but EGR fault came up.. she has been blanked off so clearly not deleted! That was the only code

Depending on what code reader you are using it may not read the suspension fault codes... only a specific diagnostic tool such as GAP or Hawkeye or LR dealer specific can read them. Also for the EGR delete, depends what year your Disco 3 is... 2004/2005 do not need a modification to the CCF (config file) to turn off the fault, but as you have seen, they still report an EGR fault when scanned, 2006 onwards need the CCF modifying using the GAP tool or similar.

If it's lowering itself to access height on its own, and then resetting to normal height when you cycle the ignition then you should definitely see some fault codes reported. It's not a leak, that would lower one corner or the front or back.

A good test would be to get it into normal height mode, and then measue the distance from the center of the wheel hub to the bottom of the wheel arch on each corner, it should be 465mm front and 485mm rear. Then remove fuse F26, this prevents the self levelling functions from working, it stops any of the valve blocks opening. It should hold at the correct height. You can drive it like this but you may get the suspension fault light coming on.

If your ride heights are off, then you will need a GAP tool coded to your car to re-calibrate it, or find someone with the pro version that can work registration free.

At the risk of sounding like a broken record, if you have the suspension fault light showing, there will be associated fault codes, you just need the right scan tool.

If you have some spare time, vist https://www.disco3.co.uk/forum/ and you will find plenty of advice on fixing D3 suspension problems.

Mat

-

You need to get the fault codes read with a GAP IID scan tool or similar, if you are anywhere near Newcastle Under Lyme Staffs, I'll gladly do it for you for free. Ordinary OBD & generic scanners cannot read the suspension diagnostic fault codes on a D3. The GAP tool is worth it's weight in gold if you have a D3.

Mat

-

a good general purpose mineral/semi-synth l 2 stroke oil is what's needed. Plenty around at reasonable prices. Stick to 25:1 and you'll be fine.

-

Regardless of the two stroke oil quality, you should stick to the original ratio (within reason) If you use a lot lower ratio of oil mix, you'll run rich, too much oil in the fuel and you'll run lean. As the carb has a fixed main jet, you'd need to jet down if you start to run 50:1 using newer synthetic oil.... on the plus side, running rich is safe for a two stroke engine, running lean can be dangerous.

-

My tidy 2005 Discovery 3 drives like a dream :-)

-

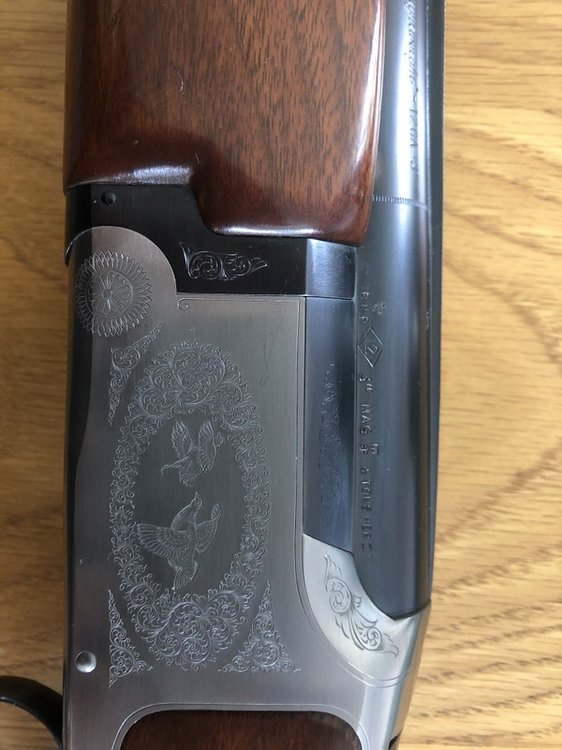

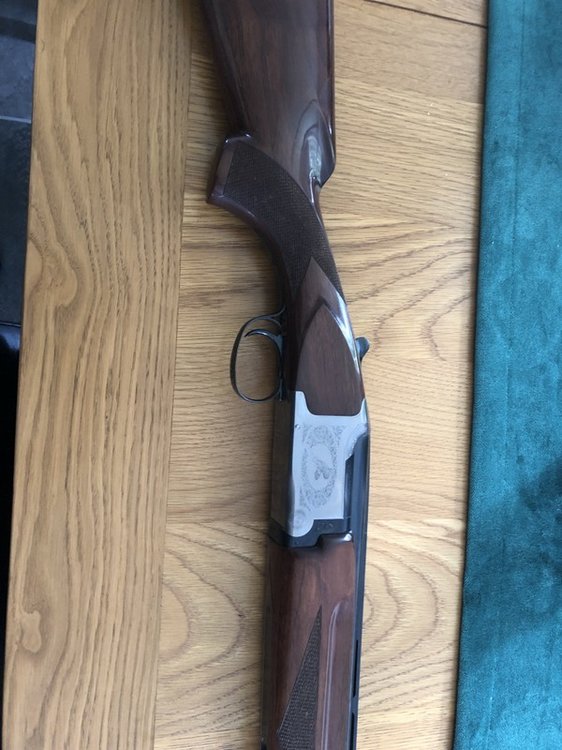

8 hours ago, TIGHTCHOKE said:

Good luck, that shouldn't be around for too long!

You were right................Sold !

-

-

On 19/06/2020 at 19:11, Salopian said:

Matgriff,

If you need any cartridges try Duncan Lawton at Croxton Post Office , just outside Eccleshall .

Failing that I have some if you require them . Newport, Shropshire 22 miles from N.u.L.

Hi, yes that's where my mates got a load from on Saturday 🙂 I paid £100 for 2 slabs of Hull superfast fibre's

-

Just been out to my local gun shop, he told me that they don't have any clay shells and haven't been able to get any for a few months due to the Coronavirus shutdown 😞

Not sure how true that is, but I came away empty handed.

Not sure about those AA trap cartridges being too good for clays... I'm a rubbish shot anyway and all cartridges are better than I am, so I usually go for the cheapest available... and they don't come much cheaper than free 🙂

Thx

-

OK thanks for the information.

I was hoping they were fibre's as I'm going on a simulated game day out next month and I need to use fiber wads only. I have a good stock of plastic wads already, but no prob I'll just have to go get another couple of slabs 🙂

Mat

-

Hi, I've recently been given 15 full boxes of cartridges 🙂

Unless I'm being particularly thick, which isn't unknown, they don't say if they are fibre or plastic wads.... maybe it's because they're pretty old and were around before plastic wads were available ??

They are Winchester AA trap 100 12ga 32g 70mm 7 1/2's

Any info welcome.

Thanks

Mat

-

I guess it all comes down to cost, a center diff is more complex and therefore more expensive... definitely an advantage for the L200, which is why its probably the choice of farmers.

-

L200 has a centre differential, so can run in permanent AWD mode on any surface at any time with no danger of transmission wind up, this is the same set-up as used on Land rovers etc....Navara's, Rangers, Dmax etc don't have a centre diff, so can only run 4WD on muddy or slippy surfaces, where the mud or snow allows the front & rear sets of wheels to turn at the same speed. If you try and run these in 4WD on tarmac it will damage the drive train.

In this respect the Mitsubishi super select is superior to the others.

-

The same pin on my old A301 broke last year, I ordered a new one, cost about £5.

The pin has two small groves, one at each end that hold it in place when you tap it in. I found the new pin was a much more snuggy fit that the old one. Try a new pin first.

-

-

Hi Smokersmith, thanks for the info. 103a is a small spring dowel pin, i've tapped that out. I tried to tap out the latch pivot pin from the bottom, ie from the side I just removed pin 103a from and it felt pretty solid, but I may have used too big a drift.. At the top side, the pivot pin sits flush to the action, you can hardly see the head of it.

I think what's happened is that the spring has broken one of the legs off, so when you squeeze in the side button, the back of the latch plate fouls on the spring as it's moved to one side, whereas the spring should sit in the middle and the latch plate presses down on either side. The net result is that the loading slide sticks in the up position, as the spring can't pull it past the slightly protruding latch plate. I've tried to show this in the bottom left corner of my photo above.

Thanks

Mat

-

Hi, I posted a few pics of a problem with my Beretta A301 semi-auto a while ago. It's been sitting in the cabinet for a while, but I've finally pulled it out and taken a better look. I think the problem is that the latch plate is sticking in the "up" position, as the carrier release spring plate can't recess back into the action fully. When I take a closer look, I think the spring (part number 101a in the picture) is broken, and is sticking under the release plate.

I've driven out the small pin under the lever (item 103a) but does anyone know how to remove the lever pivot pin 102a ? ? does it drive out from the top or from the bottom side ?

Any tips welcome, thanks

Mat

.

.

-

Hi, OK so I took a trip over to look at my Uncle's Browing B80 semi-auto, 1980's vintage. Whilst almost the same as my Beretta, there's a few small differences. On the trigger mech block the B80 has a spring loaded pin that stops the carrier plate latching in the down position. I guess this stops you having to depress the side button to load more carts ? B80 trigger is on right hand side in the above two posts.

But basically, the B80 displays the same movement to the side when the carrier plate is depressed. On my 301, there is another spring loaded catch near to the spring loaded cartridge magazine that isn't there on the B80 ??

It seems that on my 301 the side of the action where the carrier latch has been rubbing just needs to be gently dressed with some fine wet & dry to get rid of the slight ridging ? The B80 also shows signs of wear at this point.

If I fit the B80 trigger block into my 301, it behaves the same, so I know the problem isn't with the trigger mech block.

Any ideas what the extra spring latch on the opposite side to the carrier release button is for on the 301 & why it's been taken off on the B80 ? This latch can be seen on my original posed set of pictures, 2nd picture down, top right hand side of the picture. The exploded parts list in the owners manual calls it "shell latch"

Thanks

Mat

-

Yep, that's what I'm doing later :-)

-

Yes, my uncle has the exact same Browning B80.... same mechanical's as the 301 -:)

Mat

-

Yes Beretta A301. To be fair, Fenn Tiger is just using his browning by way of comparison (I think) and I think the Browning & Beretta semi-auto's of that vintage are very similar.

I'm coming to the conclusion that the problem must be the actual carrier lever/ramp itself & the pin that holds it into the trigger mech block, because it's definitely moving to the side as it slides up when the cartridge is loaded, and there is some side to side movement caused by a bit of slack in the two holes at the sides & maybe the pin. 2nd photo down in this set of pictures.

I think on the later Beretta semi-autos there is some history of bending of that carrier plate/ramp itself

Thx

Mat

-

Hi, pictures as requested. I can't see any particular issue, apart from some movement in the pin/pivot of the carrier plate in the trigger mech block. I think that could be the problem.

.jpg.3c55029fcdb1d6b862972b80763d87bb.jpg)

.jpg.940868eec48b755e75efb13260639d25.jpg)

Disco 3 intermittent fault

in Motoring Section

Posted

Not sure why you were told it's not safe to drive ?

The pipe can be replaced without removing the body or the gearbox, but it's a tricky job. There is an excellent write up and plenty of info on the Disco3 forum.